Research

Photovoltaic Technology (solar cells)

Solar cells convert sunlight directly into electricity and are being used increasingly for more sustainable power applications than ever, from desk calculators and iPod chargers, to powering satellites, space ships, power generators, and solar lighting. Solar cells are composed of semiconducting silicone materials similar to those used in computer chips. When sunlight is absorbed by these materials, the solar energy knocks electrons loose from their atoms, allowing the electrons to flow through the material, thereby producing electric current. The process of converting light (photons) to electricity (voltage) is call the photovoltaic (PV) effect.

n-type semiconductor – An extrinsic semiconductor in which the conduction electron density exceeds the hole density

p-n junction – A p-n junction is a junction formed by combining P-type and N-type semiconductors together in very close contact

p-type semiconductor – An extrinsic semiconductor in which the hole density exeeds the conduction electron density

The performance of a PV cell is measured in terms of it’s efficiency at turning sunlight into electricity. Only sunlight of certain energies will work efficiently to create electricity, and much of it is reflected or absorbed by the material that makes up the cell

ology

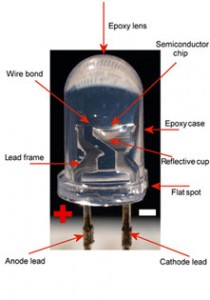

Light emitting diodes, commonly called “LEDs” have been in existence for many years. A product of accidental discovery, the technology was immediately recognized as a revolution in lighting, and has since transverse many technological fields in thousands of different implementations. LED’s are utilized for digital lighting, for transmitting information via remote control, as indicators on virtually all electronics, are even on the next generation of high definition screens. They are a consistent part of all of our lives. At virtually every point in your day, from turning to your alarm clock, to checking your watch, to stopping at a traffic sign or sitting in front of your computer, you are utilizing LED technology.

Advanced chip-type L.E.D. (implemented in the LightMark series products) |

|

|

L.E.D.s are available in many different |

||

The main advantage is efficiency. LEDs are a tiny light bulbs that fit easily into an electrical circuit, but unlike ordinary incandescent bulbs, they don’t have a filament that will burn out, a gas that fails or pollutes, and they don’t get especially hot. Traditional bulbs burns off 98% of it’s energy in heat production. LED’s are illuminated solely by the movement of electrons in a semiconductor material, and they last just as long as a standard transistor. (From 100,000 to 120,000 hours of operation). They generate little to no heat, comparatively speaking. The overwhelming majority of energy used for the emission of light.

Until recently, LEDs were too expensive to use for most lighting applications because they’re built around advanced semiconductor material. The price of semiconductor devices has plummeted over the past decade making LEDs the number one cost-effective lighting option for a wide range of situations. In many municipalities, LED lighting has already been mandated, and within the decade LEDs will be the dominant lighting technology in landscapes across the entire world.

Download the LED Application Series: Using LEDs to Their Best Advantage infosheet published by the U.S. Department of Energy to learn about the various advantages and applications for LED lighting.

For more information on LEDs and other semiconductor devices visit HowStuffWorks.com

Ultra-Capacitors

MSL- USA utilizes cutting edge ultra-capacitor energy storage in all our ground-installed LightMark™ and

LightDeco™ series products.

The ultra-capacitor technology replaces the conventional battery, and advances the next generation of energy efficiency and sustainability.

Below are some of the major advantages of the Ultra-Capacitor technology which makes it a perfect fit for our LightMark™ and LightDeco™ series products:

Lifespan

Utilizing a dry energy medium, the capacitor is able to continuously perform for an estimated average of 12 years or more.

The LightMark™ and LightDeco™ technology will not require replacement of consumables for the foreseeable future, while similar products which are battery based, consistently suffer degradation of performance within 0-3 years.

Quick Charge & Regulated Discharge

Ultra-Capacitors charge rapidly, allowing for storage of large amounts of energy over short time spans.

This energy can then be regulated while released to enhance prolonged operation. SolarPath is able to harvest sunlight at high efficiency levels, thereby harnessing energy in any weather condition, as opposed to batteries in which a fast charging algorithm further reduces their lifespan.

Temperature Resistance

Ultra-Capacitor technology creates far reaching improvements in temperature resistance.

Ultra-Capacitors can weather temperatures upward of 180F (82C) and below -22F (-30C), while batteries performance

degrade at 50% of that range.

Sustainable Technology

As a green company, the eco-friendly challenge of energy storage is at the forefront of our engineering goals.

The Ultra-Capacitor has allowed SolarPath to create lighting technologies that do not contain harmful acids, chemicals, and

other corrosive materials for use in ground applications. Additionally, they are easily and cheaply recycled.

The MSL-USA VibraProof™ Technology

The VibraProof™ technology prevents micro-flexing and micro-fracture of the solar panels and circuitry, as well as provide additional protection to the LED array. Road vibrations are a constant and serious factor in the environment in which surface based light emitting devices are installed. Delicate electronics, including circuitry, photovoltaic, energy sources, and integration mediums require maximum protections to ensure long-term operation and efficiency.

SolarPath is the only company addressing this challenging dynamic through the development of the VibraProof™ technology.

The VibraProof™ technology ensures superior longevity, and extended performance, by creating a “floating safe-zone” for the electronic components.